Research facilities are operating under increasingly tight financial constraints, and that’s not news to anyone running a lab. Labour costs keep climbing, and clinical laboratories use five to 10 times more energy per square foot than your average office building. Here’s what really stings, though: according to Lab Manager magazine surveys, many labs spend over 60% of their non-personnel budget on disposable items like pipette tips, gloves, and reagents. When you’re watching that much money go out the door on consumables, you start looking for smarter ways to operate.

Strategic Budget Optimisation

You can’t manage what you don’t measure. First step? Know exactly where your money’s going. Detailed tracking reveals patterns and identifies waste, whether you’re using spreadsheets or proper research management systems. Workflow automation has helped some facilities significantly cut manual data entry tasks. But here’s the thing: blanket budget cuts rarely work. They usually just create new problems. Better to audit regularly, spot the specific inefficiencies, and then fix those. Targeted improvements beat across-the-board slashing every time.

Reagent Management and Automation

Reagents eat up a massive portion of lab budgets. Market data from 2023 shows automated systems achieving up to 35% savings in reagent costs through precise microdispensing. That’s real money when your annual reagent budget runs into six or seven figures.

Simple practices help too. Inventory tracking prevents the nightmare scenario of finding expired reagents you forgot you had. Sharing chemicals with colleagues avoids duplicate orders and delivers immediate savings without any fancy tech required. But where automation really proves its worth is in reaction miniaturisation, shrinking reactions by a factor of 10 while keeping your experimental integrity intact. Low dead volume systems save roughly 10 times on reagents compared to traditional methods.

Automation ROI and Workflow Efficiency

The numbers on automation tell quite a story. In 2023, pharmaceutical R&D labs that adopted automated systems reduced manual labour requirements by 55% and sped up pipetting workflows by 45%. Those aren’t marginal improvements.

Modern automated liquid handling systems eliminate pipette tip costs entirely through contactless dispensing while cutting plastic waste. Staff safety improves too, with some facilities reducing manual handling by over 95%. That means fewer repetitive strain injuries and more time for work that actually requires human judgement.

One hospital laboratory achieved nearly 28% cost reduction through improved quality control design and workflow optimisation, translating to roughly $48,000 saved each quarter. Management notices results like that.

Equipment Investment Strategies

Strategic equipment procurement means balancing capability with cost-effectiveness. New purchases aren’t always the answer. Refurbished equipment, shared instrument arrangements, and leasing options all deserve consideration.

When you’re looking at automation, consider modular systems that integrate with existing infrastructure. Equipment sharing between departments provides access to advanced technology while spreading costs and building collaborative relationships.

Energy and Utility Management

Energy expenses represent controllable costs that labs frequently overlook. Ultra-low temperature freezers and laboratory refrigerators rank among the highest energy consumers, with laboratories accounting for over 60% of a major research university’s energy consumption.

Where scientifically appropriate, raising freezer temperatures from -80°C to -70°C can reduce energy consumption by 30-40% while maintaining sample integrity. And here’s one of the simplest practices: training staff to close fume hood sashes when not in use. Sounds basic, but fume hoods running 24/7 can use as much energy as 3.5 homes per year.

Technology Integration and Partnerships

Modern laboratories benefit from technologies that enhance efficiency without requiring massive capital outlay. Laboratory Information Management Systems and Electronic Laboratory Notebooks streamline operations while potentially reducing compliance-related expenses. Cloud-based solutions cut IT infrastructure costs while improving accessibility.

When evaluating automation solutions, prioritise systems with intuitive programming that empower existing staff. If your team can’t use it effectively, even brilliant technology becomes a poor investment.

Strategic partnerships extend capabilities while controlling costs. Strong supplier relationships often lead to discounts and bundled agreements. Bulk purchasing through institutional networks provides economies of scale.

Implementation and Sustainable Management

Successful cost reduction requires systematic approaches. Start with a comprehensive budget analysis to identify high-cost areas and inefficiency patterns. Not every cost centre deserves equal attention.

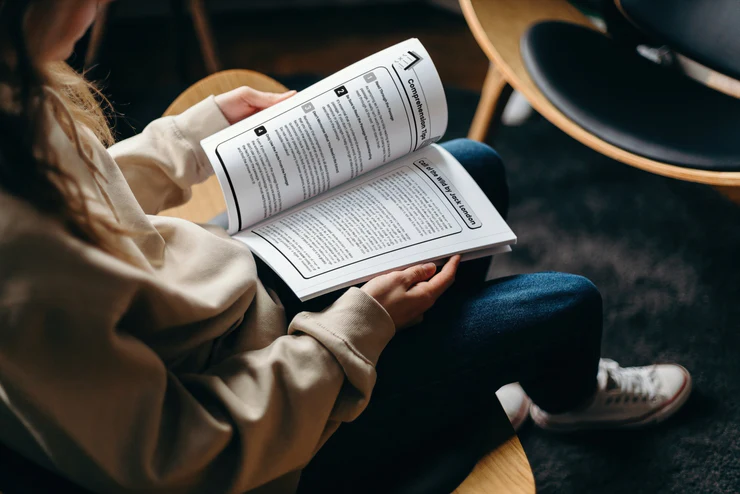

Prioritise interventions offering maximum impact relative to implementation complexity. Pilot new approaches before full deployment and measure results. Engage your laboratory staff in identifying inefficiencies. Frontline personnel recognise opportunities invisible from management perspectives.

Research excellence doesn’t require unlimited funding, although that would be welcome. Effective cost management through reagent optimisation, process optimisation, and strategic automation helps research labs preserve excellence while managing costs. The labs that succeed aren’t necessarily those with the largest budgets but those that use their budgets most effectively. Integrating technologies like automated liquid handling represents more than just cost savings. It’s a strategic investment in operational excellence that yields improved reproducibility, lower error rates, and increased research capabilities.